COMMENT DÉMARRER

Si votre projet est au stade de la planification, vous pouvez facilement entrer en contact avec l'un de nos spécialistes en ingénierie et en conception. Servez-vous de cette page pour nous décrire brièvement votre projet et nous pourrons fixer un rendez-vous immédiatement.

Why does Emission Abatement Matter?

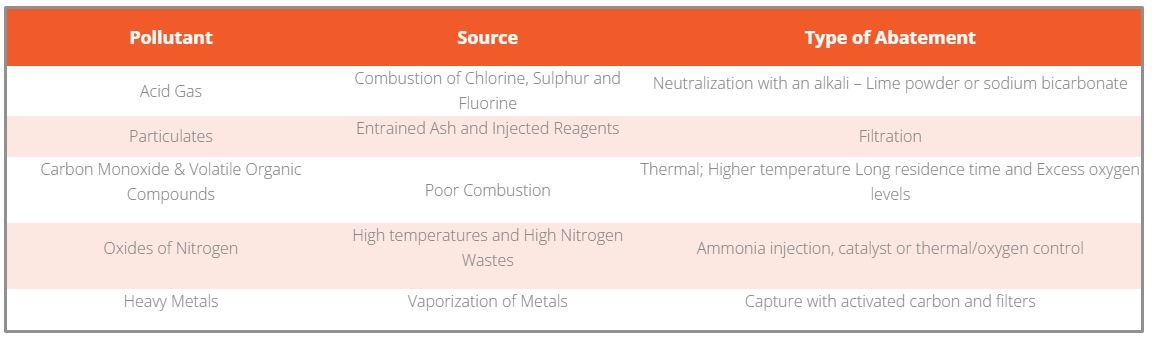

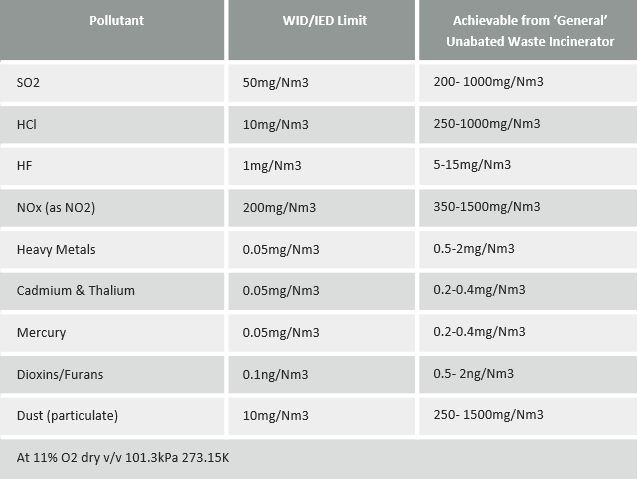

The environmental focus is so important that significant areas of the world, as well as most "blue chip" companies, abide by stringent emissions regulations specific to each region. You will see from the table the emissions achieved by a "general" waste incinerator and the emissions limits of WID/IED.

Types of Filtration Systems

Learn more about our Carbon Bed Purification System

Learn more about our NOx Reduction System

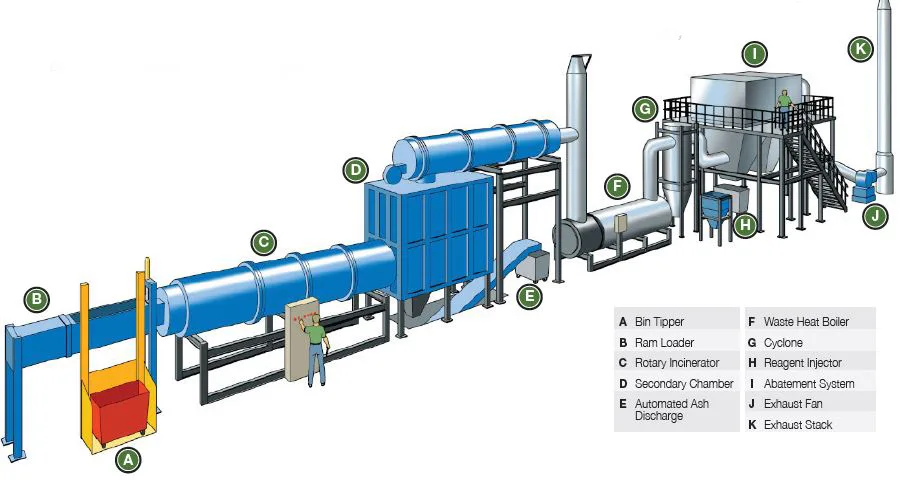

Our use of dry technology, features a combination of a reaction tower, reagent injection, and sleeve filter. Not only does this system excel in efficiently reducing levels of dust, organic substances, dioxins, mercury, and other metals, but it also offers ease of maintenance and superior plant management capabilities.

In the typical configuration, downstream of the post-combustion chamber, we integrate a precision-engineered heat exchanger. This crucial component ensures the fumes are meticulously cooled to the optimal temperature for subsequent reagent injection into the reaction tower and seamless filtration through the sleeve filter.

Learn more about our Flue Gas Abatement System